Mango Butter Making Machine

Mango Butter Making Machine Specification

- Power Source

- Electric

- Speed Mode

- Variable Speed

- Heating Method

- Electric Heating

- Machine Type

- Batch Processing

- Automation Grade

- Automatic

- Features

- Corrosion Resistant, Low Maintenance, Safety Guards

- Phase

- Three Phase

- Feeding System

- Automatic Hopper

- Operating Temperature

- Up to 120C

- Frequency

- 50 Hz / 60 Hz

- Noise Level

- 75 dB

- Function Type

- Extraction and Refining

- Product Type

- Mango Butter Making Machine

- General Use

- Mango Seed Oil and Butter Extraction

- Material

- Stainless Steel 304

- Type

- Industrial Processing Machine

- Capacity

- 200-400 kg/h

- Weight (kg)

- 650 kg

- Product Shape

- Rectangular

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Floor Mounted

- Voltage

- 380V / 220V (customizable)

- Power

- 7.5 kW

- Dimension (L*W*H)

- 1600 x 800 x 1400 mm

- Raw Material

- Mango Seed

- Feature

- High Efficiency, Energy Saving, Easy Operation

- Color

- Stainless Steel Finish

- Safety Device

- Overload and Overheat Protection

- Maintenance

- Easy to Clean and Operate

- Application

- Suitable for food, cosmetic, and pharmaceutical industries

- Finishing

- Mirror Polished Surface

- Cooling System

- In-built water cooling jacket

- Lubrication

- Automatic Greasing System

- Motor Brand

- ABB / Siemens (as per client requirement)

- Discharge Method

- Manual or Automatic Outlet Valve

- Processing Technology

- Cold & Hot Press Method

- Minimum Order Quantity

- 1 Unit

- Chamber Size

- Large Capacity Press Chamber

Mango Butter Making Machine Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Western Union, Paypal, Letter of Credit (L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Per Year

- Delivery Time

- 1 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Mango Butter Making Machine

Mango butter making mechines Coconut butter making mechines research and improvement, the peanut processing line has become a very mature product. Through different combinations of equipment, you can make different peanut foods, such as??wrap peanuts (multi-flavor peanuts, fish skin peanuts, purple potato peanuts, etc.), fried peanuts, roasted peanuts, etc. ?? The main equipments for different peanut processing lines include shelling machine, hoist, roasting machine, cooling conveyor belt, peeling machine, frying machine, mixing machine, wrap machine, swinging roasting machine, manual screening conveyor belt, colloid mill, Storage tanks, transfer pumps, mixing tanks, cooling tanks, sauce filling machines, capping machines, labeling machines, particle filling machines, etc.,??can be combined according to your production needs.Versatile Applications Across Industries

This Mango Butter Making Machine is engineered to serve food, cosmetic, and pharmaceutical sectors by efficiently extracting pure mango seed oil and butter. Its robust design and batch processing capability make it an ideal choice for manufacturers seeking reliable production for various end uses, from edible products to high-quality cosmetic formulations.

Smart Technology for Superior Output

Integrating PLC control, an automatic feeding system, and computerized automation, the machine ensures consistent and precise extraction processes. Both cold and hot press methods are available, along with electric heating and adjustable discharge options. The in-built cooling system and overload protection enhance safety and improve processing efficiency.

Durable Design and Easy Maintenance

Crafted from corrosion-resistant stainless steel 304 with a mirror finish, the machine combines durability with hygienic operation. The automatic greasing system, safety guards, and floor-mounted installation contribute to hassle-free maintenance and long-term performance, supporting easy cleaning and reliable function.

FAQ's of Mango Butter Making Machine:

Q: How does the Mango Butter Making Machine operate?

A: The machine uses cold and hot press methods to extract mango seed oil and butter. It features a large-capacity press chamber, automatic feeding, and discharge via manual or automatic outlet valves. The integrated PLC control system and variable speed ensure precise, energy-efficient processing.Q: What industries can use this machine, and what are its main applications?

A: This machine is suitable for the food, cosmetic, and pharmaceutical industries. Its primary applications include extracting mango seed oil and butter for edible products, skincare and wellness formulations, and medicinal preparations.Q: When should the cold press or hot press method be used?

A: Cold pressing is ideal for retaining more nutrients and producing premium-quality oil for cosmetic and food applications, while hot pressing can increase yield and is suitable for industrial volumes or where oil refinement is required.Q: Where can this machine be installed, and what are its installation requirements?

A: The machine is floor-mounted and requires a three-phase power supply (380V/220V, customizable). Adequate space (1600 x 800 x 1400 mm) and proper ventilation are recommended to ensure smooth operation and maintenance.Q: What is the process for cleaning and maintaining the machine?

A: Maintenance is easy due to its polished stainless steel construction and automatic greasing system. Operators need to follow standard cleaning protocols and check safety devices regularly, ensuring the machine remains efficient and hygienic.Q: How does the cooling and safety system benefit operations?

A: The in-built water cooling jacket maintains optimal operating temperature, improving machine longevity, while overload and overheat protection safeguard users and prevent mechanical failure during continuous or high-volume processing.Q: What are the main benefits of using this mango butter making machine?

A: Users benefit from high efficiency, energy savings, automated operations, and low noise (75 dB). Its corrosion resistance, variable speed, and large batch capacity (200-400 kg/h) ensure dependable, consistent output for both small- and large-scale production.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Food Processing Machinery Category

Belt Conveyor

Material : Other, Mild Steel

Speed Mode : Variable

Capacity : Customizable (up to 1000 kg/hr)

Power Source : Electric

Raw Material : Other, Mild Steel / Stainless Steel

Control System : PLC Control

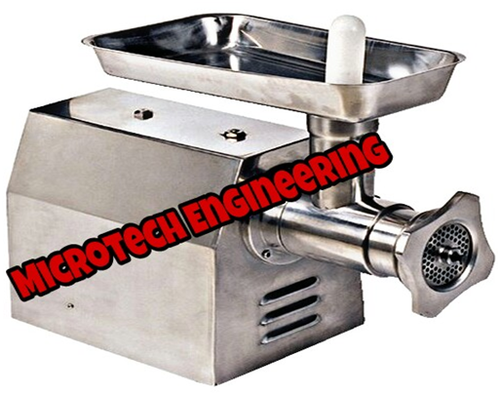

MEAT MINCER

Material : Stainless Steel

Speed Mode : other, Single

Capacity : 120 Kg per hr

Power Source : Electric

Raw Material : Other, Meat

Control System : Manual

ELECTRIC SAUSAGE FILLER

Material : Stainless Steel

Speed Mode : Variable

Capacity : 10 Liters

Power Source : Electric

Raw Material : Other, Stainless Steel

Control System : Other, Push Button Panel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry