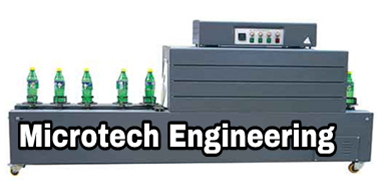

LABEL THERMAL SHRINK PACKAGING MACHINE

LABEL THERMAL SHRINK PACKAGING MACHINE Specification

- Efficiency (%)

- High efficiency (above 90%)

- Capacity

- 30-60 bottles per minute

- Media Type

- Shrink Film

- Temperature Range

- Up to 250C (for shrink process)

- Connecting Type

- Electric & Belt Conveyor Interface

- Cleaning Method

- Manual

- Condition

- New

- Material

- Stainless Steel

- Construction

- Heavy duty, compact structure

- Weight

- Approximately 300 kg

- Shape

- Rectangular body with conveyor

- Feature

- Automatic labeling and shrinking for packaging efficiency

LABEL THERMAL SHRINK PACKAGING MACHINE Trade Information

- Payment Terms

- Cash on Delivery (COD), Paypal, Western Union, Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 1 MONTH Months

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, South America, Central America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

- Certifications

- AN ISO 9001:2015 CERTIFIED

About LABEL THERMAL SHRINK PACKAGING MACHINE

Seize the opportunity to own the highly in-demand LABEL THERMAL SHRINK PACKAGING MACHINEa praiseworthy solution for packaging excellence. This premier equipment operates efficiently at 220V/380V, 50/60Hz, 3 phase, offering powerful 57 kW consumption. Its stainless steel build is compact yet valiant enough for demanding industrial environments. With PLC automatic control and a digital touchscreen HMI, the machine guarantees exceptional accuracy (1 mm) and adjustable speed. Compatible with PVC, PET, OPS shrink films, its ready-to-use for bottles, jars, and containers, delivering above 90% efficiency. Grab this offer now and automate your packaging line with superior reliability and safety.

Comprehensive Application and Ease of Use

LABEL THERMAL SHRINK PACKAGING MACHINE finds its application across industrial sites such as bottling plants, food packaging units, and chemical facilities. The direction of use involves a straightforward setup: simply load the conveyor with containers, adjust settings via the user-friendly digital touchscreen, and let the automatic system handle the rest. This machine is widely used by dealers, distributors, manufacturers, exporters, and suppliers who seek efficient, continuous operation and precise labeling results for diverse packaging requirements.

Export Markets, Shipment Timelines, and Payment Terms

This premier shrink packaging solution is exported to major markets including Asia, Middle East, Africa, and Europe. With a focus on rapid shipment, dealers and distributors typically benefit from delivery times ranging from 2 to 4 weeks post-order, depending on location and logistical factors. Expenditure is managed conveniently, as payment terms are usually flexible, accommodating advance payments, letters of credit, or other secure methods for seamless international transactions, ensuring peace of mind for all clients.

Comprehensive Application and Ease of Use

LABEL THERMAL SHRINK PACKAGING MACHINE finds its application across industrial sites such as bottling plants, food packaging units, and chemical facilities. The direction of use involves a straightforward setup: simply load the conveyor with containers, adjust settings via the user-friendly digital touchscreen, and let the automatic system handle the rest. This machine is widely used by dealers, distributors, manufacturers, exporters, and suppliers who seek efficient, continuous operation and precise labeling results for diverse packaging requirements.

Export Markets, Shipment Timelines, and Payment Terms

This premier shrink packaging solution is exported to major markets including Asia, Middle East, Africa, and Europe. With a focus on rapid shipment, dealers and distributors typically benefit from delivery times ranging from 2 to 4 weeks post-order, depending on location and logistical factors. Expenditure is managed conveniently, as payment terms are usually flexible, accommodating advance payments, letters of credit, or other secure methods for seamless international transactions, ensuring peace of mind for all clients.

FAQs of LABEL THERMAL SHRINK PACKAGING MACHINE:

Q: How does the LABEL THERMAL SHRINK PACKAGING MACHINE ensure label accuracy during operation?

A: The machine uses a PLC automatic control system and a digital touchscreen panel to maintain a label accuracy of 1 mm. The adjustable speed conveyor and precise temperature control further guarantee consistent, high-quality label shrink wrapping on every container.Q: What types of materials can this packaging machine handle for shrink labeling?

A: This machine is compatible with various shrink films, including PVC, PET, OPS, and other commercially available shrinkable films, making it versatile for different packaging needs.Q: Where is the ideal site for installing the LABEL THERMAL SHRINK PACKAGING MACHINE?

A: The ideal site is any industrial facility that requires efficient and reliable label shrink wrappingsuch as bottling plants, food manufacturing units, chemical packaging lines, or logistics hubs. The machine is floor-mounted and ready to use upon installation.Q: What is the process for cleaning and maintaining the machine?

A: Cleaning is performed manually, focusing on the conveyor, film feeding units, and labeling sections. Regular maintenance, such as lubricating moving parts and checking safety features like emergency stops, helps ensure optimal performance and longevity.Q: What are the benefits of using this machine for bottle labeling?

A: Users experience higher efficiency (over 90%), consistent labeling accuracy, reduced labor costs, and improved packaging speedprocessing 30-60 bottles per minute. The emergency stop and overload protector further enhance workplace safety during continuous operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PACKAGING AND LABELING MACHINES Category

VACUUM PACKING MACHINE(double Chamber)

Construction : Other, Robust Construction for Industrial Use

Material : Stainless Steel

Pressure : 0.1 MPa (Vacuum Pressure)

Weight : Approx. 320 kg

Feature : Double Chamber, Heavy Duty, Stainless Steel Body, Digital Control Panel, High Vacuum Efficiency

Condition : New

Automatic hot stamp machine

Construction : Other, Heavyduty, industrial build

Material : Sturdy steel body with heatresistant components

Pressure : 0.60.8 MPa (air pressure required)

Weight : Approx. 350 kg

Feature : Fully automatic operation, digital control, precision stamping

Condition : New

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry