Call: 08071931448

Cocoa Powder Production Line

Cocoa Powder Production Line Specification

- Speed Mode

- Variable Speed

- Feeding System

- Automatic Hopper Feeding

- Phase

- Three Phase

- Machine Type

- Automatic Processing Line

- Frequency

- 50 Hz

- Operating Temperature

- 0C to 60C

- Features

- Low Maintenance, Robust Construction, Operator Friendly

- Power Source

- Electric

- Function Type

- Multi-functional (Roasting, Grinding, Pressing, Powdering)

- Noise Level

- <78 dB

- Automation Grade

- Automatic

- Heating Method

- Electric / Steam

- Product Type

- Cocoa Powder Production Line

- General Use

- Industrial Cocoa Powder Manufacturing

- Material

- Stainless Steel

- Type

- Processing Line

- Capacity

- 300 - 2000 kg/h

- Weight (kg)

- 16000 kg

- Product Shape

- Horizontal Block and Vertical Tower Combination

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC based

- Installation Type

- Floor Mounted

- Voltage

- 380 V

- Power

- 65 kW

- Dimension (L*W*H)

- 16000 x 2500 x 3200 mm

- Raw Material

- Cocoa Beans

- Feature

- Continuous Operation, Energy Efficient, Modular Design

- Color

- Steel Grey / Custom

- Packaging System

- Automatic Packing Unit

- Process Stages

- Cleaning, Roasting, Winnowing, Grinding, Pressing, Drying, Powdering, Packing

- Utilities Required

- Compressed Air, Water, Electricity

- Dust Collection

- Inbuilt Dust Collector

- Control Panel Display

- Touch Screen HMI

- Cooling System

- Integrated Water Cooling

- Cleaning Mode

- CIP (Clean in Place) Supported

- Maintenance Access

- Easy Side Opening Doors

- Product Output

- Fine Cocoa Powder

- Operational Staff Required

- 2-3 Persons

- Safety Features

- Overload Protection, Emergency Stop

- Batch/Continuous

- Continuous

- Applicable Industry

- Food Processing, Confectionery, Chocolate Manufacture

Cocoa Powder Production Line Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 1 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Cocoa Powder Production Line

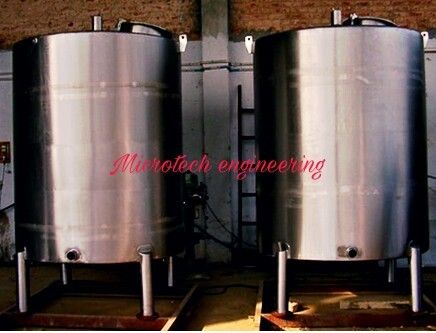

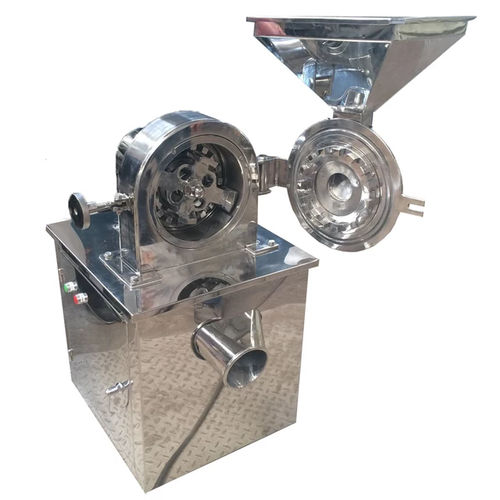

This fully automatic cocoa powder production line includes cocoa bean roasting machine, cooling air dryer, cocoa bean peeling machine, cocoa paste grinder, cocoa paste degreasing machine, cocoa powder grinder, and cocoa powder packaging machine.Comprehensive Cocoa Processing

From raw cocoa beans to high-quality cocoa powder, this production line covers every essential stage: cleaning, roasting, winnowing, grinding, pressing, drying, powdering, and automated packing. The integrated system ensures optimal product output and consistent quality ideal for industrial-scale confectionery and chocolate manufacture.

Advanced Automation & Control

Equipped with a PLC-based control system and a touch screen HMI, operators can easily monitor and adjust all process parameters. The continuous operation and automated feeding reduce manual intervention, making the line efficient and operator-friendly. Overload protection, emergency stop, and CIP cleaning further enhance safety and reliability.

Efficiency and Maintenance

Designed for low maintenance and robust construction, the line features easy side opening doors for quick access and cleaning. The modular setup with inbuilt dust collector, water cooling, and automatic packaging ensures uninterrupted operation, energy efficiency, and minimal downtime, suitable for demanding food processing environments.

FAQ's of Cocoa Powder Production Line:

Q: How does the Cocoa Powder Production Line ensure high-quality cocoa powder output?

A: The production line incorporates multiple process stages-cleaning, roasting, winnowing, grinding, pressing, drying, powdering, and packing. Each stage is controlled via PLC-based automation and monitored through a touch screen HMI. This guarantees uniform quality and consistent product characteristics for every batch.Q: What industries are suitable for this cocoa powder production line?

A: This processing line is engineered for industrial use in food processing environments, including confectionery, chocolate manufacturing, and other related sectors. Its robust modular design, energy efficiency, and high-capacity output make it ideal for manufacturers, exporters, and wholesalers across India.Q: When is regular maintenance required for optimal operation?

A: Routine maintenance can be scheduled as per the manufacturer's guidelines. The system features easy side opening doors and CIP (Clean in Place) support, allowing quick and convenient access for cleaning and servicing, which can be performed during downtime or as per usage frequency.Q: Where should the cocoa powder production line be installed?

A: The production line is floor mounted and should be placed in an industrial facility with access to three-phase electricity (380 V), compressed air, and water. Its dimensions (16000 x 2500 x 3200 mm) require substantial floor space and allow for horizontal block and vertical tower combinations.Q: What are the operational staff requirements for running the line?

A: Only two to three trained personnel are required for smooth operation, as most processes are automated and monitored via the touch screen HMI. Automatic feeding, packing, and built-in cooling and dust collection systems further reduce labor needs.Q: How does the system maintain safety during operation?

A: The production line is equipped with overload protection, emergency stop features, and an inbuilt dust collector to ensure a safe working environment. CIP support for cleaning and robust stainless steel construction also minimize health and safety risks for operational staff.Q: What benefits does the cocoa powder production line offer compared to conventional setups?

A: This automatic processing line delivers continuous operation, energy efficiency, modular design, and reliable product quality. Operator-friendly features, fast maintenance access, variable speed modes, and multi-functional capabilities (such as roasting, grinding, and powdering) significantly enhance productivity and reduce downtime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Food Processing Machinery Category

GAS FRYERS

Product Type : Gas Fryer

Speed Mode : other, Single

Feeding System : Manual

Color : Other, Silver

Phase : Single Phase

Automatic : No

ICE CUBE MAKER

Product Type : Ice Cube Maker

Speed Mode : other, Single

Feeding System : Automatic Water Inlet

Color : Other, Silver / Stainless Steel Finish

Phase : Single Phase

Automatic : Yes

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry