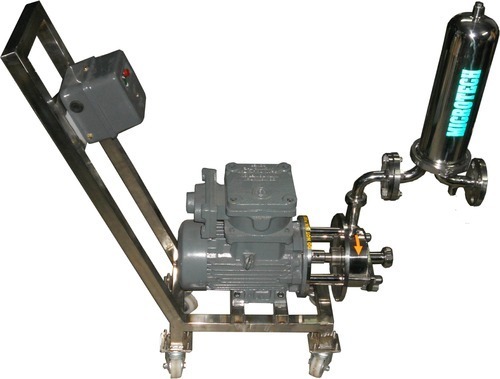

Sparkler Filter Pump

Sparkler Filter Pump Specification

- Mounting Type

- Base/Skid Mounted

- Max Suction

- Up to 4 meters

- Flow Rate

- Approx. 1000 LPH to 10000 LPH

- Caliber

- Standard

- Theory

- Centrifugal Theory

- Working Temperature

- Ambient 0C to 80C

- Head Size

- Up to 60 feet

- Features

- Leak-proof design, easy maintenance, energy efficient, corrosion resistant

- Inlet/Outlet

- 1.5 / 1.5 BSP

- Discharge Pressure

- Up to 5 bar

- Voltage

- 220-240 V

- Fuel Tank Capacity

- N/A (Electric power driven)

- Frequency

- 50 Hz

- Control System

- Manual/Automatic

- Noise Level

- Low Noise Operation

- Speed

- 2880 RPM

- Material

- Stainless Steel (SS304/316)

- Structure

- Horizontal Mount

- Power

- 0.5 HP to 3 HP

- Standard

- GMP/ISI

- Fuel Type

- Electric

- Pressure

- Max 5 kg/cm

- Usage

- Liquid Filtration, Industrial Applications

- Application

- Food, Pharmaceutical, Chemical, Beverage Industries

- Suction Type

- Positive displacement

- Seals Type

- Mechanical Seal

- Priming

- Self-priming

- Pump Type

- Sparkler Filter Pump

- Capacity

- Varies as per Model

Sparkler Filter Pump Trade Information

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Per Year

- Delivery Time

- 100 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Western Europe, Africa, Asia, Central America

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008

About Sparkler Filter Pump

Sparkler Filter Pump

SPECIF ACTION- Head : 48 meter

- Capacity :200 m3/h

- Delivery size : 12mm to 150 mm

- Temperature : -10 to 95 degree Celsius

- Test pressure : 10 kg/cm2

Standard futures :

- Centrifugal single stage

- Flange as per din standard

- Back pull out design

- Open / close impeller

- Shaft sealing by single / doable mechanical seal

- Sealed grease lubricated , deep grove ball bearing

- He pump handle liquid having viscosities up to 1500 centrioles

- Also with flame proof motor

Optional futures :

- Shaft sealing by gland packing

- Bearing lubricating by oil

- ANSI drilling on DIN flanges

- Trolley mounting arrangement

- Various type of connection

Material :

- Casing : st. Steel ( cf8 / cf8m )

- Shaft : st. Steel ( ss 410 / ss 316 / ss 304 )

- Impeller : st. Steel ( ss 410 / ss 316 / ss 304 )

- Back Plate: st. Steel ( ss 410 / ss 316 / ss 304 )

- Mechanical Seal : TC/TC , SIC/SIC TEFLON/ GFT

- MOTOR COVER : SS 304 , SS 316

- GASKET : Viton / Nitrile/ Silicon / PTFE

Reliability :

The pump are hydraulically designed for maximum efficiency. Every pump passes through stringent process & quality control plans and is designed to give longer life with consistent performance and trouble free service.

Application :

- Dairy industries

- Food processing plant

- Pharmaceutical industries

- Sugar & confectionery

- Bottling plants

- Distillery

- Beverages

- Water treatment plants

- Colors dies & pigments / paints

- Descaling application

- Sagar industries

- Hot & cold water pumping

- Sparkling filter press

- Sugar syrup

- Chemical processing

Due to content research & development data is subject to change

Exceptional Filtration Efficiency

Designed with multi-layer filter media and customizable plate diameters, the Sparkler Filter Pump delivers precise filtration for a variety of industrial liquids. Its fully enclosed, leak-proof structure supports efficient and hygienic processes across demanding sectors like food and pharmaceuticals.

User-Friendly and Low Maintenance

The pumps quick-access design allows tool-free maintenance, reducing downtime. With options for manual or automatic control, and compatibility with CIP/SIP cleaning protocols, it offers efficient servicing and flexibility for operators, improving overall productivity.

Reliable Performance and Safety

Equipped with an IP55 protection rating and mechanical seals, the pump ensures consistent operation even in high-humidity environments (up to 90% RH). Its corrosion-resistant stainless steel construction, energy-efficient motor, and self-priming capabilities guarantee dependable service for various liquid filtration applications.

FAQs of Sparkler Filter Pump:

Q: How does the Sparkler Filter Pump handle varying viscosities and flow rates?

A: The Sparkler Filter Pump is engineered to handle liquids with viscosity up to 500 cps and supports flow rates from 1000 to 10,000 LPH, making it suitable for a broad range of industrial filtration applications.Q: What safety and hygiene features does the pump offer for food and pharmaceutical use?

A: It uses food-grade silicone/nitrile gaskets, is fully enclosed and leak-proof, and complies with GMP/ISI standards. Its CIP/SIP compatibility ensures thorough cleaning and maintains high hygiene for sensitive industries.Q: Where can the Sparkler Filter Pump be installed, and how is it moved?

A: The pumps base or skid-mounted structure and castor wheels allow easy installation and mobility within factories. Its suitable for food, pharmaceutical, chemical, and beverage production areas.Q: When should the Sparkler Filter Pump undergo maintenance, and what is the process?

A: Regular maintenance can be performed quickly and tool-free thanks to its accessible design. Scheduled CIP/SIP cleaning cycles and periodic checks of the mechanical seal ensure optimal performance and longevity.Q: What benefits does its centrifugal theory design provide for industrial filtration?

A: Using centrifugal theory, the pump achieves high efficiency and consistent flow while reducing energy consumption. This ensures effective filtration and supports scalable operations in diverse industrial environments.Q: How is the pumps leak-proof design advantageous during operation?

A: The fully enclosed, leak-proof construction prevents fluid loss, enhances workplace safety, and protects processed liquids from environmental contamination, especially important in regulated industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sanitary Pump Category

SS Hygienic Pump

Minimum Order Quantity : 01

Material : SS304 / SS316 Stainless Steel

Usage : Other, Food & Beverage, Pharmaceutical, Dairy, Chemical

Pressure : Other, Up to 6 Bar

Flow Rate : Up to 60 m/hr

Sanitary Filtration Pump

Price 15302.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : stainless steel

Usage : Water, Oil Well, Water Well, Food, Boat, Other, Air Pump, Cosmetics

Pressure : Medium Pressure

Flow Rate : 100 lph to 100000 lph

Sanitary Filter Pump

Material : Stainless Steel 304/316L

Usage : Other, Liquid Filtration

Pressure : Other, Up to 4 bar

Flow Rate : 325 m/h

Sparkler Filter Press Pump

Price 16518.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : stainless steel

Usage : Water, Water Well, Food, Boat, Automobile, Air Pump, Cosmetics, Other, Paper Printer, Oil Well

Pressure : Medium Pressure

Flow Rate : 100 lph to 100000 lph

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry