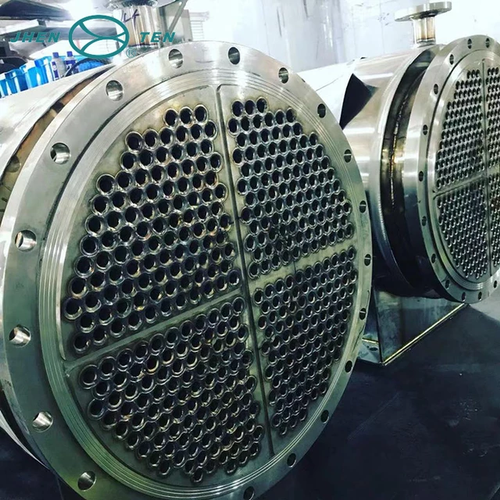

Shell And Tube Heat Exchangers

Product Details:

X

Product Description

Shell and Tube Heat Exchangers, Pressure Vessels, Columns, Filter Dryers, Reactors and Complete Pre-Assembled Units Features: 1. Intensified Heat Transfer The spiral copper coil pipe is fixed by the cantilever construction. As the hot mediators(saturation steam or high-temperature water)pass the pipe, The pipe’s high-speed round trip motion causes perturbation motion of the water around the heat exchanger tubes forcedly, and this increases the heat transfer coefficient “Kâ€, reduces the fluid‘s thermal resistance on the tubes outer wall “l/a0â€, and enhances the total heat transfer coefficient.2. Less solid fouling Bcause of the coil pipe‘s float with high speed, the fouling will be deposited and adheres to the pipe’s outer wall difficultly during the operation process. At the same time, Even though there is a little fouling on the pipe’s outer wall, the fouling will break off automatically because the coil pipe will flex along with temperature change,therefore the traditional fouling-release technique is needless and the heat exchanger can keep the best work condition for long term.3. The accurate temperature controlThe heat exchanger is collocated with the high-accuracy “intellectualized temperature adjusterâ€, it can inspect the water temperature continuously and automatically and will instruct the controlling valves to regulate the flowing quantity of the hot mediator in the coil pipe, the outlet water temperature will be kept in the scope of ±2°C of the set point in the case that the charge is waving. 4. Less floor spaceThe exchanger has compact structure,so the floor space required is only 10 percent of the tubular heat exchanger that has the same function. The fabrication cost is reduced and space is utilized efficiently, it is also convenient for hoisting assembly and transportation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Chemical Machinery' category

|

MICROTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free Send SMS

Send SMS