Call: 08071931448

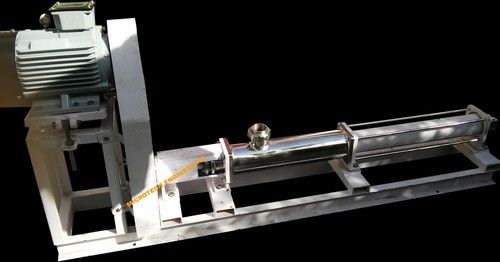

Progressive Cavity Pumps

Progressive Cavity Pumps Specification

- Inlet/Outlet

- 1.5 x 1.5

- Features

- Non-clogging, Low pulsation, Accurate dosing

- Noise Level

- Low (70 dB)

- Mounting Type

- Base Mounted

- Max Suction

- Up to 7 M

- Frequency

- 50 Hz

- Caliber

- DN40 / DN50

- Working Temperature

- Up to 150C

- Head Size

- Up to 48 M

- Theory

- Progressive Cavity

- Flow Rate

- Up to 22 m/hr

- Control System

- Manual / Automatic

- Discharge Pressure

- 0.6 MPa

- Speed

- Up to 300 RPM

- Voltage

- 415 V

- Material

- Stainless Steel / Cast Iron

- Structure

- Single Screw Rotor & Stator

- Power

- 0.75 7.5 kW

- Standard

- ISO 9001

- Fuel Type

- Electric

- Pressure

- Up to 6 Bar

- Usage

- Industrial / Chemical / Food Processing

- Application

- Effluent Transfer, Sludge Handling, Viscous Liquids

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self-Priming

- Pump Type

- Horizontal Progressive Cavity

- Capacity

- Customizable per requirement

Progressive Cavity Pumps Trade Information

- Supply Ability

- 200 Per Year

- Delivery Time

- 200 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About Progressive Cavity Pumps

Unlock the power of Trending, top-drawer engineering with our Progressive Cavity Pumpssizzling in the industrial market for their potent efficiency and terrific adaptability. Designed for viscosity ranges up to 100,000 cSt, these pumps excel in handling slurries up to 10%. Featuring heavy-duty bearings, IP55 protection, and robust alloy/stainless-steel rotors, they deliver consistent performance in diverse environments, even at high temperatures (up to 150C). Enjoy non-clogging, self-priming operation, accurate dosing, low pulsation, and ultra-low noise, making them a top choice for dealers, exporters, and manufacturers across India.

Progressive Cavity Pumps: Diverse Applications & Surfaces

These trending Progressive Cavity Pumps are ideally suited for effluent transfer, sludge handling, viscous liquid transfer, and even food processing. Their robust design and positive displacement action unlock reliable performance on demanding surfaces such as industrial flooring, process plant lines, and wastewater treatment facilities. Specifically tailored for moving heavy, abrasive, or chemically aggressive fluids, they ensure top-drawer results and minimal maintenance in chemical processing, pharmaceuticals, and slurry transport, among many specialist applications.

Export Markets, Sample Drop-offs, and Packaging Details

We supply our potent Progressive Cavity Pumps across a sizzling international export market, covering regions such as Europe, the Middle East, Africa, and Southeast Asia. Sample policies are crafted for easy drop-off and client evaluation, facilitating a smooth vendor-client relationship. Packaging is tailored to guarantee safety, using robust crates and moisture-proof materials, ensuring pumps arrive in pristine condition. Serving as suppliers, dealers, and manufacturers from India, we seamlessly handle bulk and customized orders.

Progressive Cavity Pumps: Diverse Applications & Surfaces

These trending Progressive Cavity Pumps are ideally suited for effluent transfer, sludge handling, viscous liquid transfer, and even food processing. Their robust design and positive displacement action unlock reliable performance on demanding surfaces such as industrial flooring, process plant lines, and wastewater treatment facilities. Specifically tailored for moving heavy, abrasive, or chemically aggressive fluids, they ensure top-drawer results and minimal maintenance in chemical processing, pharmaceuticals, and slurry transport, among many specialist applications.

Export Markets, Sample Drop-offs, and Packaging Details

We supply our potent Progressive Cavity Pumps across a sizzling international export market, covering regions such as Europe, the Middle East, Africa, and Southeast Asia. Sample policies are crafted for easy drop-off and client evaluation, facilitating a smooth vendor-client relationship. Packaging is tailored to guarantee safety, using robust crates and moisture-proof materials, ensuring pumps arrive in pristine condition. Serving as suppliers, dealers, and manufacturers from India, we seamlessly handle bulk and customized orders.

FAQs of Progressive Cavity Pumps:

Q: How does the bidirectional rotation feature benefit Progressive Cavity Pump usage?

A: The bidirectional rotation allows flexible installation and operation by enabling fluid flow in both directions, simplifying system design, and easing maintenance workflows in industrial applications.Q: What types of fluids can these Progressive Cavity Pumps handle confidently?

A: These pumps confidently manage a variety of fluids including viscous liquids, effluents, sludges, and slurries with up to 10% solid content, supporting chemical, food, and wastewater industries.Q: Where can I install Progressive Cavity Pumps in industrial applications?

A: They are suitable for installations in chemical plants, food processing lines, wastewater treatment complexes, and other demanding industrial environments requiring reliable dosing and fluid transfer.Q: What is the process for customizing the capacity of these pumps?

A: You can specify the required flow rate, head, and operational parameters. The manufacturer then tailors the pumps configuration to match your applications demands, ensuring optimal and efficient operation.Q: When should mechanical seal or gland packing be used for these pumps?

A: Mechanical seals are preferred for aggressive or high-pressure fluids, minimizing leakage, while gland packing is cost-effective and suitable for less demanding or standard applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Progressive Cavity Pumps Category

Screw Pumps

Pressure : Other, High

Usage : Other, Industrial

Pump Type : Other, screw pumps

Material : Mild Steel

Features : Heavy Duty

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry