Pneumatic Butterfly Valve

Pneumatic Butterfly Valve Specification

- Air Inlet

- 1/4 BSP

- Surface Treatment

- Epoxy coated / Painted

- Capacity

- Full Port

- Diameter

- 50 mm to 400 mm

- Pressure

- PN10 / PN16

- Pattern Dimensions

- To ISO 5211

- Thread size

- ISO Standard

- Operating Pressure

- 4-8 bar

- Air Consumption

- 0.05 m3/cycle

- Product Type

- Pneumatic Butterfly Valve

- Material

- Cast Iron / Stainless Steel / Aluminum Alloy

- Metals Type

- Stainless Steel / Cast Iron

- Usage

- Industrial automation, water treatment, chemical processing

- Size

- 2 inch to 16 inch

- Weight

- 2.3 kg

- Leakage Class

- Class VI (Bubble Tight)

- Mounting

- Direct Mount Actuator

- Torque Requirement

- 10 Nm to 180 Nm

- Position Indicator

- Mechanical or Visual Status Indicator Available

- Operation

- Single Acting (Spring Return) / Double Acting Pneumatic Actuator

- Media Compatibility

- Water, Air, Oil, Chemicals

- Body Coating

- Powder Coated / Epoxy Painted

- Connection Type

- Wafer / Lugged / Flanged

- Seat Material

- EPDM / PTFE / NBR / Viton

- Disc Material

- Stainless Steel / Ductile Iron / Nylon coated

- Seal Type

- Bubble Tight Shutoff

- Valve Design Standard

- ISO 5211 / EN 593

- Temperature Range

- -20°C to 120°C

Pneumatic Butterfly Valve Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cheque, Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Per Year

- Delivery Time

- 2 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Pneumatic Butterfly Valve

Pneumatic Butterfly Valve

Moc SS/PVC/ALUMINIUM /CI

We are manufacturer of Aluminum Die Cast body Butterfly Valves wiht pneumatic actuator that is precisely manufactured using high-grade raw material and the latest technology with the set universal standards. These valves are thoroughly checked against various parameters under the supervision of our skilled professionals to ensure defect-free deliveries.

Reliable Shutoff Performance

Engineered with a bubble-tight Class VI shutoff, this valve ensures zero leakage. The robust seat and disc options, along with powder-coated or epoxy-painted body, guarantee longevity even in demanding chemical and water treatment applications. The direct actuator mounting simplifies automation and maintenance.

Versatile Industrial Applications

Ideal for environments requiring precise, automated flow control, the valve supports media like chemicals, water, air, and oils. Its multiple seat and disc combinations, wide temperature range, and full port capacity make it a preferred solution for manufacturers, fabricators, and suppliers across India.

Flexible Design and Standards Compliance

With connection types including wafer, lugged, and flanged, the valve fits diverse piping systems. It conforms to ISO 5211 and EN 593, ensuring interchangeable installation. The mounting pattern and air inlet specifications provide compatibility with standard pneumatic automation setups.

FAQ's of Pneumatic Butterfly Valve:

Q: How does the pneumatic butterfly valve achieve bubble-tight shutoff?

A: The valve uses high-quality seats such as EPDM, PTFE, NBR, or Viton and a precision-engineered disc to ensure bubble-tight Class VI shutoff, preventing any leakage even under demanding operating conditions.Q: What is the benefit of using different disc and seat materials in this valve?

A: Choosing disc materials like stainless steel, ductile iron, or nylon coated, and seats such as EPDM, PTFE, NBR, or Viton, allows compatibility with various fluid media, enhancing corrosion resistance, longevity, and performance based on specific process requirements.Q: When should a single acting actuator be chosen over a double acting type?

A: A single acting pneumatic actuator is preferred when failsafe closure is necessary in emergency situations, as it uses spring return, while double acting actuators are ideal where bi-directional control and greater torque are required.Q: Where can this pneumatic butterfly valve be installed?

A: The valve is suitable for installations in industrial automation systems, chemical processing plants, water treatment facilities, and any application requiring precise flow control for liquids or gases, across piping sizes 2 to 16 inches.Q: What is the typical process for mounting the actuator on this valve?

A: The actuator mounts directly to the valve following ISO 5211 pattern dimensions, ensuring easy, secure attachment without the need for additional adapter plates. This streamlines installation and maintenance.Q: How does the visual or mechanical position indicator support valve operation?

A: A position indicator provides immediate feedback on valve status, enhancing operational safety and allowing operators to monitor open or closed positions during remote or automated control sequences.Q: What advantages does full port capacity offer in industrial usage?

A: Full port design ensures minimal flow restriction, enabling efficient fluid handling and reducing energy consumption, especially in processes where maintaining high throughput and consistent pressure is critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spray Nozzle Category

Penumatic Diaphargm Valve

Pressure : PN10

Surface Treatment : Polished

Usage : Industrial Fluid Control

Size : DN15 to DN100

Material : Polypropylene & Stainless Steel

AIR ATOMIZING NOZZLES FLAT JET / FULL CONE

Minimum Order Quantity : 01

Pressure : 2 to 7 bar

Surface Treatment : Nickel Plated / Polished

Usage : Industrial Spray Applications

Size : 1/4 inch, 3/8 inch, 1/2 inch

Material : Brass / Stainless Steel

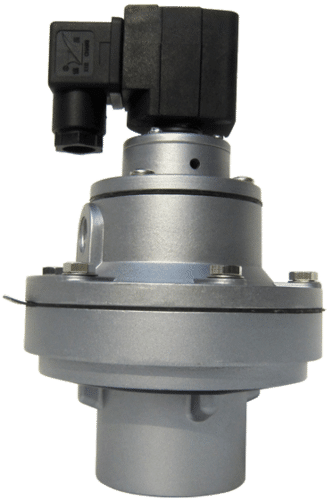

Dust Collector Solenoid Valve

Pressure : 0.5 8 Kg/cm

Surface Treatment : Anodized Finish

Usage : Industrial Dust Collectors

Size : 1 inch, 1.5 inch, 2 inch (available options)

Material : Aluminum Alloy Body, Nitrile Rubber Diaphragm

Condensate, Seal Pots

Pressure : Up to 6000 PSI

Surface Treatment : Polished/Sand Blasted

Usage : Steam pipeline application, protection of instrumentation

Size : 2 inch to 8 inch

Material : Stainless Steel (SS 304/316), Carbon Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry