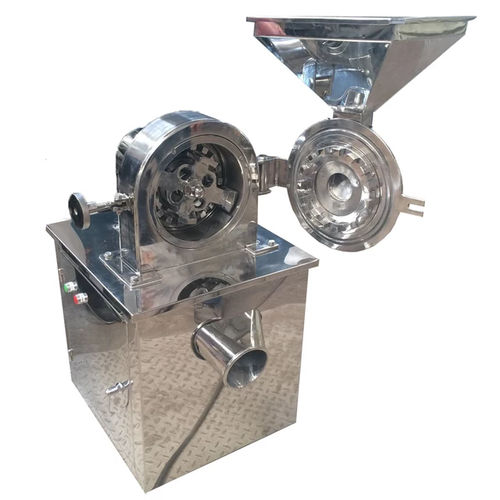

Peanut Powder Making Machine

Peanut Powder Making Machine Specification

- Phase

- Three Phase

- Operating Temperature

- Normal Ambient

- Function Type

- Grinding & Pulverizing

- Frequency

- 50 Hz

- Machine Type

- Peanut Milling Machine

- Features

- Easy Maintenance, Robust Construction

- Speed Mode

- Adjustable

- Noise Level

- Low

- Power Source

- Electric

- Automation Grade

- Automatic

- Feeding System

- Hopper

- Product Type

- Food Processing Machinery

- General Use

- Industrial Peanut Powder Production

- Material

- Stainless Steel

- Type

- Powder Making Machine

- Capacity

- 80-100 kg/hr

- Weight (kg)

- 320 kg

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Yes

- Control System

- Button Panel

- Installation Type

- Floor Mounted

- Voltage

- 380V

- Power

- 4 kW

- Dimension (L*W*H)

- 1200 x 650 x 1350 mm

- Raw Material

- Peanut

- Feature

- High Efficiency, Easy Operation

- Color

- Silver

- Drive Type

- Belt Driven

- Cleaning System

- Manual Cleaning

- Output Particle Size

- 40-60 mesh

- Safety Features

- Overload Protection

- Usage/Application

- Food Industry, Commercial Kitchen

- Processing Type

- Continuous

- Surface Finish

- Polished

Peanut Powder Making Machine Trade Information

- FOB Port

- yes

- Payment Terms

- Paypal, Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 1 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Peanut Powder Making Machine

Advanced Performance and Efficiency

This automatic peanut powder maker is engineered for seamless, high-capacity operation. The powerful 4 kW motor and robust stainless steel body ensure efficient grinding, handling up to 100 kg of peanuts per hour. Its adjustable speed and overload protection optimize performance while maintaining safety.

User-Friendly and Easy Maintenance

Designed with commercial users in mind, the machine features a simple button panel, easy hopper feeding, and accessible manual cleaning system. The polished surface reduces residue build-up, simplifying cleaning and reducing downtimes, while its sturdy construction promotes long-lasting reliability.

FAQ's of Peanut Powder Making Machine:

Q: How does the peanut powder making machine process operations for continuous production?

A: The machine operates continuously by taking in raw peanuts through a hopper and grinding them with precision into a fine 40-60 mesh powder. The belt-driven mechanism and automatic function allow for steady output, making it ideal for commercial and food industry needs.Q: What safety features are included in this peanut powder making machine?

A: This machine is equipped with overload protection to prevent damage during heavy loads, ensuring operator safety and extending the machine's lifespan. The robust stainless steel construction further enhances safety in the working environment.Q: When is manual cleaning recommended for the peanut powder machine?

A: It is advisable to conduct manual cleaning at the end of each production shift or whenever switching between different batches. The straightforward cleaning system makes maintenance easy, ensuring consistent hygiene and machine efficiency.Q: Where can this machine be installed for optimal performance?

A: The peanut powder making machine is designed for floor mounting in commercial kitchens or food production facilities. Its compact design (1200 x 650 x 1350 mm) fits efficiently into various industrial layouts across India.Q: What are the benefits of using this machine for industrial peanut powder production?

A: Key benefits include high efficiency, consistent particle size, minimal noise, robust construction, easy operation, and adaptability for large-scale commercial or industrial food production. Its automatic operation minimizes labor and maximizes productivity.Q: How is the output particle size controlled and adjusted during use?

A: The machine features adjustable speed modes on its button panel, allowing operators to fine-tune processing as needed to consistently achieve the desired 40-60 mesh output particle size.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Automatic Tablet Coater- Film & Sugar Coating

Material : Stainless Steel

Product Shape : Other, Round Drum

Color : Other, Stainless Steel/Silver

Weight (kg) : 1600 kg

Dimension (L*W*H) : 2450 x 1700 x 2100 mm

Cocoa Powder Production Line

Material : Stainless Steel

Product Shape : Other, Horizontal Block and Vertical Tower Combination

Color : Other, Steel Grey / Custom

Weight (kg) : 16000 kg

Dimension (L*W*H) : 16000 x 2500 x 3200 mm

RUTF Processing Plant

Material : Other, Stainless Steel (SS304/SS316)

Product Shape : Other, Rectangular Modular Plant

Color : Other, Silver & Grey (Stainless Steel Finish)

Weight (kg) : 5500 kg

Dimension (L*W*H) : 8000 x 3500 x 4200 mm

DRINK MIXER

Material : Other, Stainless Steel & ABS Plastic

Product Shape : Other, Upright Cylindrical

Color : Other, Silver

Weight (kg) : 3.5 kg

Dimension (L*W*H) : 210 x 180 x 500 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry