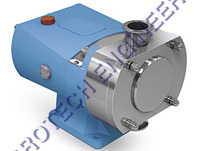

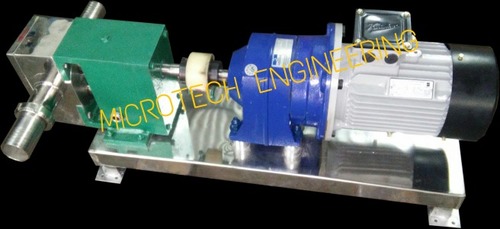

Ointment Transfer Pump

Ointment Transfer Pump Specification

- Working Temperature

- Up to 80C

- Max Suction

- 5 meter

- Mounting Type

- Trolley or Fixed

- Head Size

- Up to 32 meter

- Features

- Sanitary Design, Easy to Clean, Non-Clogging

- Noise Level

- Below 70 dB

- Frequency

- 50 Hz

- Theory

- Centrifugal Pump

- Caliber

- 25 mm to 50 mm

- Inlet/Outlet

- 1/1

- Flow Rate

- 300 to 5000 LPH

- Voltage

- 220-415 V

- Speed

- 960-1440 RPM

- Control System

- Manual / Automatic

- Discharge Pressure

- Up to 3 bar

- Material

- Stainless Steel (SS316/SS304)

- Structure

- Horizontal

- Power

- 1-5 HP

- Standard

- cGMP

- Fuel Type

- Electric

- Pressure

- Up to 3 bar

- Usage

- Industrial Fluid Transfer

- Application

- Ointment, Cream, Gel, and Paste Transfer

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal

- Priming

- Self-Priming

- Pump Type

- Screw/Helical Rotor

- Capacity

- Up to 5000 LPH

- Number of Stages

- Single stage

- Weight

- 80-120 kg (approx.)

- Cleaning Method

- CIP/SIP compatible

- Automation Grade

- Semi-Automatic/Fully Automatic

- Direction of Rotation

- Clockwise/Counter Clockwise

- Surface Finish

- Mirror Polished

- Connections

- Tri-Clamp/Flanged

- Viscosity Handling

- Up to 100000 CPS

- Electrical Protection

- IP55 Motor

Ointment Transfer Pump Trade Information

- FOB Port

- yes

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Western Union, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- South America, Western Europe, Eastern Europe, Middle East, Central America, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Ointment Transfer Pump

Ointment Transfer Pump

Microtech engineering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

Optimized for Challenging Fluids

Engineered to handle viscous products up to 100,000 CPS, this pump ensures reliable and clog-free transfer of ointments, creams, and gels. The non-clogging, screw/helical rotor design allows for continuous operation, minimizing downtime and maintaining consistent output.

Sanitary and Easy to Clean

With a mirror-polished stainless steel construction and compatibility with CIP/SIP processes, this pump supports strict hygiene requirements typical in pharmaceutical and cosmetic manufacturing. Its design allows for efficient cleaning and minimizes product residue.

Flexible Control and Operation

Adaptable for both manual and automatic control systems, the pump can be integrated into existing production lines. Options for trolley or fixed mounting provide mobility and stability, enabling usage in a range of industrial environments.

FAQ's of Ointment Transfer Pump:

Q: How does the ointment transfer pump handle high viscosity products?

A: This pump employs a screw/helical rotor mechanism capable of efficiently transferring high-viscosity fluids up to 100,000 CPS, such as ointments, creams, and gels, with minimal risk of clogging.Q: What cleaning methods are supported for this pump?

A: The pump is compatible with both CIP (Clean-In-Place) and SIP (Sterilize-In-Place) systems, making it ideal for industries with stringent hygiene standards and ensuring quick, effective cleaning between batches.Q: When should I choose semi-automatic versus fully automatic operation?

A: Semi-automatic mode is suitable for smaller production lines or when manual monitoring is required. Fully automatic operation is ideal for larger, continuous processes, providing ease of integration and consistent performance.Q: Where can this pump be installed in a production facility?

A: The pump is available with both trolley and fixed mounting options, allowing it to be stationed where needed in your facility-next to mixing tanks, filling equipment, or along production lines.Q: What are the benefits of the pump's sanitary design?

A: The sanitary design, featuring a mirror-polished SS316/SS304 body and tri-clamp connections, prevents product contamination, simplifies cleaning, and meets cGMP standards for pharmaceutical and food industries.Q: How is electrical safety ensured during operation?

A: The pump is equipped with an IP55-rated motor, which provides robust protection against dust and water, ensuring safe and reliable operation in demanding industrial conditions.Q: What types of industrial fluids can the pump transfer?

A: Primarily designed for ointments, creams, gels, and pastes, the pump can also be used for other viscous fluids within the industrial, pharmaceutical, and cosmetic sectors, provided viscosity and temperature limits are observed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lobe Pump Category

Lobe Pump

Minimum Order Quantity : 01

Material : SS304 / SS316 / Cast Iron

Pressure : Other, Up to 10 Bar

Theory : Other, Rotary Lobe Pump

Head Size : Up to 24 m

STARCH TRANSFER PUMP MANUFACTURERS IN INIDA

Price 65028.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : stainless steel

Pressure : Medium Pressure

Theory : Rotary Pump

Head Size : 10m to 70m

STARCH TRANSFER PUMP MANUFACTURING IN INDIA

Minimum Order Quantity : 1 Unit

Material : stainless steel

Pressure : Medium Pressure

Theory : Rotary Pump

Head Size : 10m to 70m

Mayonnaise Transfer Pump

Minimum Order Quantity : 1 Number

Material : stainless steel

Pressure : Medium Pressure

Theory : Rotary Pump

Head Size : 100m

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry