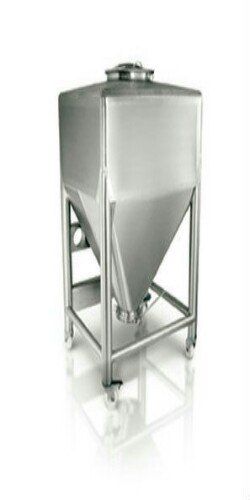

IPC Bin - Intermediate Process Container

IPC Bin - Intermediate Process Container Specification

- Temperature

- Ambient or as per process

- Noise Level

- Silent operation

- Usage & Applications

- Pharmaceutical, Chemical, and Food Processing Industries

- Features

- Crevice free internal surface, GMP compliant, easy cleaning, robust construction

- Type

- Intermediate Process Container (IPC Bin)

- Material

- Stainless Steel 304 / 316

- Capacity

- 10L to 500L (Customizable)

- Computerized

- No

- Control Mode

- Manual

- Weight (kg)

- Varies by capacity, typically 15kg to 90kg

- Dimension (L*W*H)

- Custom as per requirement

- Color

- Metallic Silver

- Cleaning

- Suitable for CIP & SIP

- Non-contact Parts

- SS 304 / Mild Steel Powder Coated

- Lid Type

- Clamp-type / Hinged Lid

- Discharge Type

- Butterfly Valve / Manual Discharge

- Product Contact Parts

- SS 316 as per GMP

- Sealing

- Silicone Gasket provided for airtight sealing

- Handles

- Lifting Handles for Safe Handling

- Corrosion Resistance

- High

- Operating Pressure

- Atmospheric

- Mobility

- Fitted with Castor Wheels

- Shape

- Conical / Cylindrical

- Application Range

- Granules, Powders, Intermediate Bulk Products

- Surface Finish

- Mirror Polish / Matt Finish

IPC Bin - Intermediate Process Container Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About IPC Bin - Intermediate Process Container

IPC BIN - INTERMEDIATE PROCESS CONTAINERStorage and Dust free transfer Process

Application & Process :

Bin (IPC) is a container made from SS 316 sheets having cylindrical Body and taper bottom. A lid is provided on top. The lid is big so that complete washing the IPC is easy. The Bin is seated on a detachable stand or fixed leg made of SS 304 pipe stand, having forelegs and each leg is fitted with heavy duty castor wheel of special design with ball bearing and SS side frame (2 nos. fixed and 2 Nos swiveling).Bin (IPC) are used for handling, storing, transporting and mixing of pharmaceutical powders and granules before, between and after various processes. They are designed and manufactured to be handled through their own trolley and offer the advantage to leave the trolley at floor when the container is raised up to be positioned onto process machines like tablet presses, sachet filling machines etc.The IPC Bin loader is use for transfer the material dust free and without human touch in pharmaceutical industries for Load powder in to RMG bowl, Load powder in to hopper of tablet press, Load tablet in to hopper of blister pack & Coating Machine and online sifting and milling.The IPC Bin Loader consists of a main frame, Bin fixing arm, Hydraulic lifting device and pivot base. This main frame move 360 degree on axis and Bin fixing arm move upward and downward in the frame by hydraulic cylinder and power pack system. The moveable container/Bin bringing placed beneath the fixing arm, operate the hydraulic drive system which lifts arm with the container and it raises the container till it gets stops exactly in a position and then it could be unload by opening of butterfly on the what ever machine.Salient Features :

Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316/316L & non contact parts AISI 304. Capacity available from 30 Kg to 600 Kg. Universal bin handling and stacking system for easy automated handling and stacking of bins Charging through the top opening. Discharging through bottom discharge butterfly valve. Without any nooks and corners for easy cleaning with food grade silicon gaskets. Mirror finish from inside and adequate hopper angle for easy and complete discharge of products Option for various type of IPC Bin as per customer requirement.

Versatile Design for Diverse Processing Needs

Our IPC Bins are available in both conical and cylindrical shapes, with a wide array of customizable options for capacity, discharge type, and lid configuration. This flexibility makes them ideal for applications in pharmaceutical, chemical, and food processing industries, streamlining intermediate product handling and transfer processes while ensuring product integrity and operational efficiency.

GMP Compliance and Hygienic Handling

Every IPC Bin is manufactured using SS 316 for product contact parts and SS 304 or powder-coated mild steel for non-contact areas. With mirror/matt surface finish and crevice-free internal surfaces, these bins facilitate easy, thorough cleaning and meet stringent Good Manufacturing Practice (GMP) standards, ensuring safe handling of sensitive products at every process stage.

Reliable Sealing and Enhanced Mobility

Designed with a silicone gasket for airtight sealing and equipped with lifting handles and lockable castor wheels, IPC Bins ensure safe, spill-free transport of contents within your facility. Silent operation and robust construction enable smooth movement while maintaining the highest levels of safety and cleanliness.

FAQ's of IPC Bin - Intermediate Process Container:

Q: How does the IPC Bin support safe and hygienic handling in processing industries?

A: The IPC Bin is built with crevice-free, mirror/matt finished stainless steel and fitted with silicone gaskets for airtight sealing. It features lifting handles and robust castor wheels for safe handling and movement, supporting strict hygiene protocols in pharmaceutical, chemical, and food processing environments.Q: What is the cleaning process for the IPC Bin?

A: The IPC Bin is designed for easy cleaning and maintenance. It is compatible with both Clean-In-Place (CIP) and Sterilize-In-Place (SIP) procedures, ensuring thorough cleaning and sterilization without needing to disassemble components, which saves time and maintains product quality.Q: When should I choose a mirror polish versus a matt finish surface for the IPC Bin?

A: A mirror polish surface is ideal for processes demanding minimal product retention and the highest hygiene, as it provides smoother surfaces for quicker and more efficient cleaning. Matt finish is suitable when glare reduction or cost efficiency is a priority without compromising on cleanliness.Q: Where can IPC Bins be used in manufacturing processes?

A: IPC Bins are suited for intermediate storage, transfer, and discharge of granules, powders, and bulk products. They are widely utilized in pharmaceutical, chemical, and food processing industries for handling products between different stages of the manufacturing process, ensuring controlled, clean transfer.Q: What benefits do the butterfly valve and manual discharge options provide?

A: The butterfly valve enables precise and controlled discharge of materials, minimizing spillage and dust generation. Manual discharge options are available for simpler operations, catering to different process requirements and operator preferences.Q: How customizable are IPC Bins in terms of size and configuration?

A: IPC Bins can be tailored according to required capacity, typically ranging from 10L to 500L. Additional customization is available for shape, lid type, discharge mechanism, and dimensions, ensuring optimal integration into existing production lines.Q: What advantages does stainless steel construction offer in IPC Bins?

A: Using SS 316 for product contact parts ensures high corrosion resistance, durability, and compliance with GMP standards. SS 304 or powder-coated mild steel for non-contact areas adds strength and economy, enhancing the bin's longevity and safety in demanding process environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Tablet Coating Pan

Usage & Applications : Used for coating tablets in pharmaceutical and food industries

Features : Easy to operate, corrosion resistance, smooth finishing

Dimension (L*W*H) : 1150 x 900 x 1550 mm

Color : Silver

Power : 1.52.25 kW

Weight (kg) : 240 kg

Vibro Sifter

Usage & Applications : Pharmaceutical, Chemical, Food, and Agro Industries for sieving and gradation

Features : High sieving accuracy, Robust construction, Easy cleaning, Low maintenance

Dimension (L*W*H) : Customized as per model (e.g. 900mm x 900mm x 1400mm)

Color : Silver

Power : 0.5 HP to 2 HP (Model Dependent)

Weight (kg) : 120 kg to 250 kg (Approx)

Fluidized Bed Dryer

Usage & Applications : Pharmaceutical, Food, Chemical, and Herbal Industries for Drying Granules, Powders

Features : Efficient Drying, GMP Model, Uniform Fluidization, Explosion Proof Design, Easy Cleaning, Energy Efficient

Dimension (L*W*H) : Customizable (Standard: 1700 x 1050 x 1900 mm)

Color : Silver

Power : 315 kW

Weight (kg) : Varies as per model (approx. 3501200 kg)

Tray Dryer

Usage & Applications : Drying of pharmaceuticals, chemicals, food products, dyestuffs, and more

Features : High efficiency, uniform drying, low maintenance

Dimension (L*W*H) : Customizable; standard: 1800 x 1200 x 2100 mm (varies by capacity)

Color : Silver (Stainless Steel Finish)

Power : 636 kW (model dependent)

Weight (kg) : 380 1350 kg (according to model)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry