Call: 08071931448

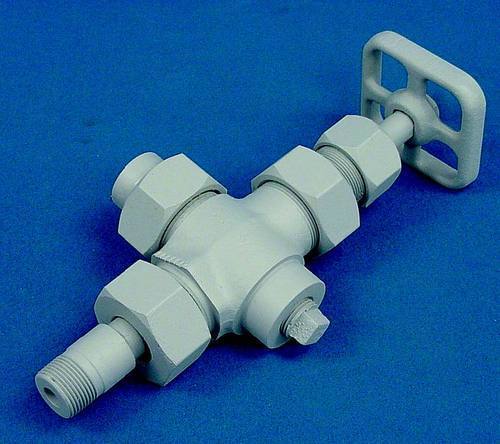

Instrumentation Tube Fitting

Instrumentation Tube Fitting Specification

- Caliber

- Varies by tube OD: 1/8 to 1 (3 mm to 25 mm)

- Mounting Type

- Panel Mounting, Inline, Bulkhead

- Control System

- Manual Installation

- Features

- Easy installation, vibration resistance, corrosion-resistant

- Working Temperature

- -20C to 204C (depending on seal material)

- Inlet/Outlet

- Threaded connections, typically NPT, BSP, or metric

- Material

- 316 Stainless Steel, Brass, Monel

- Structure

- Double Ferrule (Compression), Single Ferrule

- Standard

- ASTM, ANSI, DIN, JIS

- Pressure

- Up to 6000 psi (414 bar) depending on size and material

- Usage

- Leak-tight connection of instrumentation and process tubing

- Application

- Chemical, Petrochemical, Power Plants, Oil & Gas, Analytical Instruments

- Seals Type

- PTFE, Viton, Nitrile

Instrumentation Tube Fitting Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Western Union, Paypal, Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Per Year

- Delivery Time

- 1 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Instrumentation Tube Fitting

We sell Single and Double Compression Tube Fittings which are designed for process and Instrumentation tubing which provides a leak proof torque free seal at all the tubing connections, thus eliminating hazardous and costly leaks

Unmatched Corrosion Resistance

Built using premium-grade 316 stainless steel, Monel, or brass, these tube fittings excel in highly corrosive environments. Electropolished and passivated finishing options enhance protection, making them ideal for chemical and petrochemical industries where reliability and longevity are critical requirements.

Versatile Connection and Thread Types

Choose from double ferrule, single ferrule, or customized fittings with a broad selection of threads including NPT, BSPT, BSPP, Metric, and UNF. The diverse range ensures secure, adaptable connections compatible with global instrumentation standards and a variety of pipe specifications.

Reliable Performance Across Applications

Withstanding temperatures from -20C to 204C and pressures up to 6000 psi, these fittings are optimal for demanding applications in oil & gas, power plants, analytical labs, and water management systems. PTFE, Viton, or Nitrile seals provide further chemical compatibility and leak resilience.

FAQs of Instrumentation Tube Fitting:

Q: How do I select the correct ferrule type for my instrumentation tube fitting?

A: The choice between double ferrule, single ferrule, or custom options depends on application-specific needs such as pressure, vibration, and ease of installation. Double ferrule fittings offer superior holding power and leak prevention, while single ferrule designs simplify assembly. Consult technical specifications or an expert for optimal selection.Q: What thread options are available for these tube fittings?

A: Our instrumentation tube fittings are available with NPT, BSPT, BSPP, Metric, and UNF threads. This extensive range ensures compatibility with different international standards and makes integration into new or existing systems seamless.Q: When should electropolished or passivated finishes be specified?

A: Electropolished or passivated finishes are recommended when fittings are used in highly corrosive environments, such as chemical and petrochemical plants. These finishes improve corrosion resistance and extend service life, especially when working with aggressive fluids or gases.Q: Where are these fittings typically used?

A: Instrumentation tube fittings find application in chemical processing, petrochemical, oil & gas industries, power plants, analytical laboratories, and water treatment facilities. Their robust performance ensures leak-tight connections in critical process and control systems.Q: What benefits do these fittings provide in industrial systems?

A: They deliver leak-free connections, high corrosion resistance, and vibration resistance, which ensures process reliability and safety. Easy installation and compatibility with various tubing and thread types streamline system design and maintenance.Q: How should these fittings be installed and maintained?

A: Installation is manual and should follow recommended torque values specific to each size and type. Regular inspection for signs of wear or leaks ensures long-term performance. Always use compatible seals (PTFE, Viton, or Nitrile) as specified for the operating medium.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pharmaceutical Pump Category

SS Pharmaceutical Pump

Application : Other, Pharmaceutical, Biotech, Food, Chemical Industries

Frequency : 50 Hz / 60 Hz

Mounting Type : Base Plate / Portable Skid / Flanged

Theory : Other, Centrifugal / Positive Displacement

Material : SS316 / SS316L / SS304 Stainless Steel

Discharge Pressure : Up to 8 kg/cm

LG Valve

Application : Other, Water Control, Industrial Automation

Frequency : 50/60Hz

Mounting Type : Inline/Threaded

Theory : Other, Solenoid Valve

Material : Brass

Discharge Pressure : Same as Inlet Pressure

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry