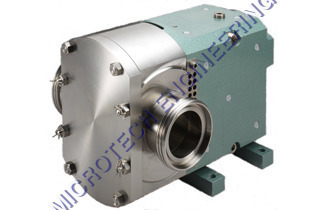

High Viscosity Paste Transfer Pump

High Viscosity Paste Transfer Pump Specification

- Speed

- 200-960 rpm

- Theory

- Rotary Pump

- Voltage

- 220V / 380V

- Caliber

- DN40

- Max Suction

- 7 meters

- Mounting Type

- Horizontal

- Working Temperature

- -10C to 120C

- Noise Level

- Low Noise

- Inlet/Outlet

- 1.5 inch / 1.5 inch

- Control System

- Optional VFD & Remote Control

- Flow Rate

- 100-6000 L/H

- Discharge Pressure

- Up to 0.6MPa

- Head Size

- 15-80 meters

- Frequency

- 50/60Hz

- Features

- Corrosion Resistant, Easy to Clean, Low Shear, Leak Proof, CIP/SIP Capability

- Material

- Stainless Steel 304/316L

- Structure

- Gear Pump

- Power

- 1.5-7.5 kW

- Standard

- ISO / CE certified

- Fuel Type

- Electric

- Pressure

- 0.6 MPa Max

- Usage

- Industrial Paste Transfer

- Application

- Suitable for High Viscosity Paste, Honey, Cream, Glue, Syrup, Paint, etc.

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal

- Priming

- Self-priming

- Pump Type

- High Viscosity Paste Pump

- Capacity

- Adjustable

- Protection

- Overload and Dry Run Protection

- Rotor Type

- Lobe / Gear / Screw (customizable)

- Drive Type

- Electric motor driven

- Surface Finish

- Mirror Polished

- Ambient Temperature

- -5°C to +40°C working environment

- Cleaning Method

- CIP (Clean-in-place) Supported

- Portability

- Movable with Trolley (optional)

- Connection Type

- Tri-Clamp / Flange Available

- Viscosity Range

- Up to 200,000 cps

High Viscosity Paste Transfer Pump Trade Information

- Minimum Order Quantity

- 01 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 100 Years

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CHARGE

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2008 MSME

About High Viscosity Paste Transfer Pump

High Viscosity Paste Transfer PumpMicrotech Engineering

Lobe Pumps Are Used In A Variety Of Industries Including, Pulp And Paper, Chemical, Food, Beverage, Pharmaceutical, And Biotechnology. They Are Popular In These Diverse Industries Because They Offer Superb Sanitary Qualities, High Efficiency, Reliability, Corrosion Resistance, And Good Clean-In-Place And Sterilize-In-Place (Cip/Sip) Characteristics. These Pumps Offer A Variety Of Lobe Options Including Single, Biwing, Tri-Lobe (Shown), And Multi-Lobe.Rotary Lobe Pumps Are Non-Contacting And Have Large Pumping Chambers, Allowing Them To Handle Solids Such As Cherries Or Olives Without Damage. They Are Also Used To Handle Slurries, Pastes, And A Wide Variety Of Other Liquids. If Wetted, They Offer Self- Priming Performance. A Gentle Pumping Action Minimizes Product Degradation. They Also Offer Reversible Flows And Can Operate Dry For Long Periods Of Time. Flow Is Relatively Independent Of Changes In Process Pressure, So Output Is Constant And Continuous.

Reliable High Viscosity Paste Transfer

Designed for the challenges of high-viscosity materials, this pump delivers precise transfer performance even with the thickest substances. Its self-priming and positive displacement features ensure consistent flow and pressure, making it suitable for a vast range of applications from food processing to chemical manufacturing. The robust stainless steel construction and mirror-polished surface facilitate hygienic operation while minimizing product contamination.

Flexible and Easy Maintenance

Adaptability is at the heart of this pumps design. Choose between lobe, gear, or screw rotors to match your process needs. Maintenance is simplified with CIP (Clean-in-place) compatibility, so routine cleaning is efficient and thorough. Overload and dry run protections safeguard the pump and inflate operational longevity. Movability through trolley mounting enables swift relocation wherever needed in the facility.

FAQs of High Viscosity Paste Transfer Pump:

Q: How do I clean and maintain the High Viscosity Paste Transfer Pump?

A: The pump is designed with CIP (Clean-in-place) capability, allowing thorough internal cleaning without disassembly. Simply run the cleaning solution through the system according to the manufacturers instructions. Routine inspections for seals and mechanical parts are also advised to ensure lasting performance.Q: What types of fluids can this pump handle, and what is the maximum viscosity it supports?

A: This pump efficiently transfers high-viscosity pastes, such as honey, syrup, glue, cream, and paint, with viscosities up to 200,000 cps. Its robust positive displacement mechanism and customizable rotors are designed for challenging, thick fluids common in industrial applications.Q: When should I use the movable trolley option for this pump?

A: The trolley-mounted version is ideal for operations requiring frequent relocation or where installation flexibility is essential. This portable option enables you to use the pump across different workstations or processes, reducing downtime and enhancing operational versatility.Q: Where can the High Viscosity Paste Transfer Pump be installed?

A: This pump is suited for industrial environments across India and globally, operating effectively in ambient temperatures from -5C to +40C and working temperatures up to 120C. Its horizontal mounting type and compact design allow for easy integration into production lines.Q: What are the key benefits of using this pump for industrial paste transfer?

A: Key benefits include precise and adjustable flow rates, low noise operation, high resistance to corrosion, easy cleaning, reliable leak-proof sealing, and overload/dry run protections. These features enhance safety, efficiency, and product quality, meeting ISO and CE standards.Q: How does the pump ensure product quality during operation?

A: The low shear, leak-proof design, combined with mirror-polished stainless steel and optional remote control, minimizes contamination risk and mechanical stress on delicate materials, ensuring product consistency and integrity throughout the transfer process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lobe Pump Category

Shampoo transfer pump manufacturers in india

Minimum Order Quantity : 1 Unit

Usage : Water, Air Pump, Oil Well, Water Well, Food, Automobile, Boat, Cosmetics, Other, Paper Printer

Material : STAINLESS STEEL

Pressure : Medium Pressure

BUMP LOBE PUMP

Minimum Order Quantity : 01 Piece

Usage : Other, Industrial; Chemical, Food Processing, Dairy

Material : Stainless Steel (SS304, SS316) / Cast Iron

Pressure : Other, 0.5 to 8 Bar

Pump Type : Other, Positive Displacement

Features : Hygienic design, Easy Clean, CIP/SIP compatible, Low Shear Handling

Syrup Transfer Pump

Minimum Order Quantity : 01

Usage : Other, Syrup Transfer / Food Industry

Material : Stainless Steel (SS 304/316)

Pressure : Other, Low to Medium

Pump Type : Other, Sanitary Pump

Features : Hygienic design, Easy to Clean, Corrosion Resistant

Honey Transfer Pump

Minimum Order Quantity : 01 Piece

Usage : Other, Honey Transfer

Material : Stainless Steel

Pressure : Other, 1.8 bar

Pump Type : Other, Lobe/Rotor

Features : Corrosion resistant, Easy cleaning, Low maintenance

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry