Hand Operated Drum Barrel Pump

Hand Operated Drum Barrel Pump Specification

- Head Size

- Up to 15 m

- Voltage

- Manual, Not Applicable

- Features

- Portable, Lightweight, Easy to Operate, Corrosion Resistant

- Mounting Type

- Drum Mounted

- Control System

- Manual Control

- Inlet/Outlet

- Inlet: 38 mm / Outlet: 25 mm Hose

- Max Suction

- Max. Suction Lift: 5 m

- Noise Level

- Silent/Low Noise

- Caliber

- Fit for 210L/55 Gallon Drums

- Discharge Pressure

- Up to 2.5 Bar

- Speed

- Depends on Operator (Manual)

- Flow Rate

- 250-300 ml per revolution

- Working Temperature

- -10C to 60C

- Theory

- Rotary Hand Pump

- Material

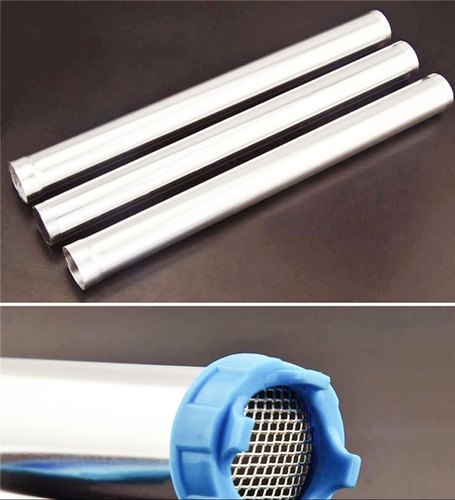

- Aluminum/Polypropylene/Stainless Steel Barrel

- Structure

- Rotary Drum Pump

- Power

- Manual Operation

- Standard

- ISI/ISO Certified Components

- Fuel Type

- Suitable for Non-corrosive Liquids

- Pressure

- Atmospheric

- Usage

- Oil, Diesel, Chemicals

- Application

- Industrial, Garage, Workshop, Agriculture, Chemical Handling

- Suction Type

- Hand Operated/Suction Lift

- Seals Type

- Viton / NBR Seals

- Priming

- Self-priming

- Pump Type

- Hand Rotary Drum Barrel Pump

- Capacity

- Dispenses 20-25 Liters per Minute (Approx.)

- Surface Finish

- Polished/Powder-Coated (Depending on Material)

- Package Includes

- 1 Drum Barrel Pump, 1 Discharge Hose, Installation Kit

- Suction Tube Length

- 930 mm 1000 mm

- Handle Length

- Approximately 30 cm

- Compatibility

- Fits Standard 200L/210L Drums

- Weight

- 2.5 - 4 kg (Depending on Model)

- Maintenance

- Minimal Easy Disassembly for Cleaning

- Discharge Hose Length

- 800 mm 900 mm

- Color

- Silver/Blue (Varies by Material)

Hand Operated Drum Barrel Pump Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cheque, Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Per Year

- Delivery Time

- 3 Week

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Hand Operated Drum Barrel Pump

Hand Operated Drum Barrel Pump

We are a trusted manufacturer and supplier of top grade Pumps and Process Control Instruments. With a premier aim to cater to the varied demands and requirements of our client in an efficient manner, we offer a comprehensive array of products comprising Transfer Pump, Polypropylene Pump, Stainless Steel Self Priming Pump, Filter Pump, Magnetic Drive Pump, Dosing Pump and Process Control Instruments. All these products are developed in compliance with the international quality standards.

Efficient Drum Emptying Solution

This hand-operated rotary drum pump can dispense approximately 20-25 liters per minute, streamlining the process of liquid transfer in industrial and commercial environments. The pump fits standard 200L/210L drums and includes all essential accessories for immediate setup, making it an ideal choice for various sectors including agriculture and workshops.

Built for Durability and Ease of Use

With its polished or powder-coated surface, this pump resists corrosion and delivers longevity even in demanding settings. Designed to be drum mounted, lightweight, and portable, it can be quickly disassembled for cleaning and maintenance, ensuring reliable performance with minimal downtime.

FAQ's of Hand Operated Drum Barrel Pump:

Q: How do I install the hand operated drum barrel pump on a standard drum?

A: Installation involves attaching the suction tube to the pump, securing the discharge hose, and mounting the pump onto the drum's opening. The included installation kit provides all necessary components. Simply follow the manual for a quick setup, suitable for 200L/210L drums.Q: What types of liquids can this pump handle safely?

A: This rotary hand pump is compatible with non-corrosive fluids such as oil, diesel, and chemicals. It features Viton/NBR seals that ensure safety and durability when handling various liquids within industrial or agricultural environments.Q: When should I perform maintenance on the drum barrel pump?

A: Minimal maintenance is required due to its robust design. It is advisable to disassemble and clean the pump after handling viscous or residue-leaving liquids, or periodically as part of routine equipment upkeep to ensure continued optimal performance.Q: Where can the drum barrel pump be used effectively?

A: This pump is suited for use in industrial sites, garages, workshops, agricultural operations, and chemical handling facilities across India, offering flexibility thanks to its portable and drum-mounted design.Q: What is the benefit of the manual rotary pump design over electric pumps?

A: Manual rotary pumps are lightweight, portable, silent, and do not require electricity. This allows safe and controlled liquid transfer even in remote or outdoor locations, providing significant operational flexibility.Q: How does the pump's self-priming feature enhance operation?

A: The self-priming mechanism allows the pump to start effectively without pre-filling, reducing setup time and simplifying the transfer process, making it easy to use even for new operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Barrel Emptying Pump Category

Barrel Mixing & Emptying Pump

Minimum Order Quantity : 01

Usage : Other, Barrel mixing & transferring liquids

Material : SS 316 / Polypropylene (PP)

Control System : Manual ON/OFF switch

Mounting Type : Barrel/top mounting

Features : Integrated mixing function, corrosion resistance, portable design, easy cleaning

Piston Type Barrel Pump

Usage : Other, Transfer of Light Oils, Kerosene, Diesel & NonCorrosive Liquids

Material : Aluminum Alloy Body with Steel Piston

Control System : Manual Crank Handle Operation

Mounting Type : Vertical Mounting into Barrel

Features : Portable, Easy to Install, Resistant to Corrosion

Barrel Emptying Pump

Minimum Order Quantity : 01

Usage : Other, Industrial Barrel Emptying

Material : Stainless Steel / PP

Control System : Manual

Mounting Type : Portable

Features : Corrosion Resistant, Lightweight, Easy to Clean

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry