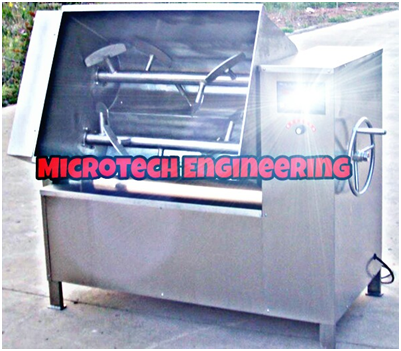

FILLING MIXER

FILLING MIXER Specification

- Feeding System

- Top Feeding

- Heating Method

- Electric Heating

- Power Source

- Electric

- Frequency

- 50/60 Hz

- Machine Type

- Batch Mixer

- Automation Grade

- Automatic

- Noise Level

- Low

- Operating Temperature

- Up to 90C

- Function Type

- Mixing and Filling

- Speed Mode

- Variable Speed

- Phase

- Single Phase / Three Phase

- Features

- Easy to Clean, Energy Saving

- Product Type

- Filling Mixer

- General Use

- For Mixing and Filling Applications

- Material

- Stainless Steel 304

- Type

- Industrial Mixer

- Capacity

- 500 Ltr/batch

- Weight (kg)

- 350 kg

- Product Shape

- Round

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC based

- Installation Type

- Floor Mounted

- Voltage

- 220-240 V

- Power

- 3 kW

- Dimension (L*W*H)

- 1200 x 800 x 1600 mm

- Raw Material

- Stainless Steel

- Feature

- Corrosion Proof, High Efficiency, Low Maintenance

- Color

- Silver

FILLING MIXER Trade Information

- Payment Terms

- Cash on Delivery (COD), Western Union, Paypal, Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 1 MONTH Months

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Asia, Central America, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

- Certifications

- AN ISO CERTIFIED

About FILLING MIXER

Our entity is offering FILLING MIXER. These products are widelyutilized in the market for their reliable performance and longer operationallife. Our presented product is made as per universal industry norms utilizingthe reliable component, bought from reliable sellers of market. Due to topperformance, clientele widely utilize these products.

FEATURES:

All the parts contacting the food directly are made of stainlesssteel.

Highly Efficient and Safe Operation

Equipped with an ABB/Siemens motor and overload protection, the Filling Mixer delivers efficient and reliable mixing within a 530 minute adjustable timeframe. The automatic PLC-based control system ensures consistent operation while minimizing the risk of mechanical failures. Anti-vibration pads enhance stability during high-speed mixing, optimizing safety and machine lifespan.

Superior Hygiene and Easy Cleaning

Crafted from mirror-polished stainless steel 304 and featuring CIP (Clean-In-Place) compatibility, the mixer meets stringent cleanliness requirements in industrial settings. Its bottom discharge and round design prevent material buildup, facilitating thorough cleaning between batches. This focus on hygiene suits industries demanding sanitary processing, such as food, pharmaceutical, and cosmetic sectors.

Flexible Installation and Versatility

The floor-mounted Filling Mixer, with its compact dimensions and fixed anti-vibration setup, is suitable for a range of plant layouts. Variable speed and a wide operating temperature (up to 90C) enable handling of diverse products. Whether used by manufacturers, wholesalers, or exporters in India, the system adapts effortlessly to batch mixing, filling, and heating processes.

FAQs of FILLING MIXER:

Q: How does the Filling Mixer ensure consistent and efficient blending?

A: The mixer features a PLC-based automatic control system and a powerful ABB/Siemens motor that allows precise adjustment of mixing time (5 to 30 minutes) and variable speed settings. This, combined with its anchor/agitator shaft and bottom discharge, ensures uniform blending in every batch.Q: What cleaning process is recommended for this mixer?

A: The Filling Mixer is designed to be CIP (Clean-In-Place) compatible. This allows users to clean the equipment efficiently without disassembly, which saves time and maintains hygienic conditions, especially important in food and pharmaceutical applications.Q: When is this mixer suitable for use in industrial production?

A: This industrial mixer is ideal for batch operations that require high efficiency, thorough mixing, and reliable heating. Its construction and automation make it a preferred choice in continuous, large-scale production environments where consistency and safety are essential.Q: Where can the Filling Mixer be installed and how is it mounted?

A: Designed for floor-mounted installation, the mixers fixed frame and anti-vibration pads ensure stable operation. Its compact footprint (1200 x 800 x 1600 mm) allows easy integration into various industrial settings with single or three-phase electric supply.Q: What benefits does the mirror-polished stainless steel finish provide?

A: The mirror-polished stainless steel 304 finish enhances corrosion resistance, makes the surface easy to clean, and prevents contamination. This results in long-lasting durability and suitability for industries with strict hygiene requirements.Q: How does the safety system protect the mixer during operation?

A: The integrated overload protection system continuously monitors motor performance, automatically stopping the mixer in case of overload. This prevents potential damage and contributes to operational safety and reduced maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bakery Equipments Category

ICE CUBE MAKER

Control System : Other, Microcomputer / Electronic

Features : Energy Saving, Fast Ice Production, Easy Cleaning

Raw Material : Other, Stainless Steel

Weight (kg) : 40 kg

Color : Other, Silver / Stainless Steel Finish

General Use : Hotels, Restaurants, Cafes, Bars

SOAP TUREEN

Control System : Manual

Features : Detachable lid, durable, easy to clean

Raw Material : Other, Plastic

Weight (kg) : 0.15

Color : White

General Use : Holding soap

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry