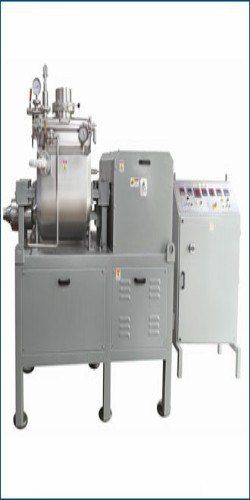

Dispohomo Reactor: High Shear Dispersion Homogenizer

Dispohomo Reactor: High Shear Dispersion Homogenizer Specification

- Temperature

- Ambient to 120C (with heating/cooling jacket)

- Noise Level

- <75 dB

- Phase

- Three Phase

- Usage & Applications

- Dispersion, homogenization, emulsification of liquids, creams, gels; used in pharmaceuticals, cosmetics, chemicals, food processing

- Frequency

- 50 / 60 Hz

- Features

- CIP/SIP compatible, quick dismantling, precision shaft seal, variable speed, high shear mixing, explosion proof motor option

- Type

- High Shear Dispersion Homogenizer

- Material

- Stainless Steel (SS304/SS316 contact parts)

- Capacity

- 50 to 10,000 Liters (customized as per requirement)

- Computerized

- Optional (with PLC automation integration)

- Control Mode

- Manual / Automatic

- Voltage

- 220V / 380V / 415V (customizable)

- Power

- 5 kW to 55 kW depending on model & capacity

- Weight (kg)

- Approx. 450 kg 2500 kg depending on vessel size

- Dimension (L*W*H)

- Customized as per model; typical: 1700mm x 1200mm x 2100mm

- Color

- Silver / Metallic

- Spare Parts Availability

- Easy access and replacement

- Ambient Humidity

- Up to 90% RH

- Jacketed Vessel

- Available (for heating/cooling)

- Viscosity Handling

- Up to 100,000 cP

- Mixer Mounting

- Top/Side/Bottom entry (configurable)

- Batch/Continuous Operation

- Available for both modes

- Cleaning

- Designed for Clean-In-Place (CIP)

- Installation Type

- Floor mounted skid system

- Liquid Contact Finish

- Mirror polished (Ra <0.4 m)

- Inlet/Outlet

- Sanitary tri-clamp fittings

- Pressure Rating

- Atmospheric to 8 Bar

- Shaft Sealing

- Mechanical double seal with cooling

- Safety Features

- Overload protection, emergency stop, interlocking guards

- Homogenizing Principle

- Rotor-Stator High Shear Emulsification

- Impeller Type

- Multiport rotor-stator disperser

- Process Control

- Digital display, programmable controls

- Sanitary Design

- GMP compliant, crevice-free surfaces

- Speed Range

- 103000 RPM (variable frequency drive)

Dispohomo Reactor: High Shear Dispersion Homogenizer Trade Information

- FOB Port

- yes

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Year

- Delivery Time

- 3 Week

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- PACKING, WOODEN BOX

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Asia, Central America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Dispohomo Reactor: High Shear Dispersion Homogenizer

DISPOHOMO REACTOR: HIGH SHEAR DISPERSION HOMOGENIZER

Liquid High Shear Homogenize mixing and dispersing inline process Application & Process :

Macrotech Engineering has been developed a new modular construction series for high shear homogenizer. With this Dishomo reactor series of machines it became possible to carry out different process steps like dispersing with "high shear", milling or continuous mixing of solids and liquid with only a few modules.Dishomo reactor delivers unparalleled consistency and control of high shear process applications such as, Immiscible Phase Emulsifying, Homogenizing, Wet Grinding, Texturing, Deagglomeration and Fine Dispersing.A three-stage high - shear dispersing machine for the production of macro-emulsions and very fine suspensions. Due to the three generators (rotor-stator) in direct series a narrow distribution range, smaller droplets and particles and thus a longer stability of the mixture are reached. The generators are easily dismantles for clean and wash.

Technical Specification :

Model PDH - 2000Max Flow capacity. 2500 liters- H2O / hoursDrive speed 1/min 4400Motor Power 5.5 Kw / 7.5 HPConnection Inlet DN 40Connection Outlet DN 32Sealing Mechanical Seal with continues cooling

Efficient High Shear Homogenization

Driven by a multiport rotor-stator disperser, the Dispohomo Reactor achieves superior mixing, particle size reduction, and efficient emulsification. Its high shear mechanism guarantees uniformity and stability for a broad range of viscosities, making it ideal for advanced formulations in pharmaceuticals, cosmetics, and specialty chemicals.

Flexible Operation and Control

Designed with both batch and continuous operation capability, the reactor addresses diverse production needs. Its programmable digital controls and optional PLC integration offer precise adjustment of mixing parameters for reproducible results. Speed variability ensures suitability for delicate emulsions and high-viscosity blends alike.

Optimal Safety and Sanitary Standards

The unit meets stringent GMP requirements with crevice-free, mirror-polished surfaces and fully sanitary tri-clamp fittings. It provides enhanced operator safety through overload protection, emergency stop, and interlocked guards, while the clean-in-place (CIP) design streamlines maintenance and minimizes contamination risks.

FAQ's of Dispohomo Reactor: High Shear Dispersion Homogenizer:

Q: How does the Dispohomo Reactor achieve high shear dispersion and homogenization?

A: The Dispohomo Reactor operates using a rotor-stator high shear emulsification principle, where the multiport disperser rapidly imparts intense shear forces. This mechanism breaks down particles and droplets, efficiently blending and emulsifying even high-viscosity materials for uniform and stable product consistency.Q: What types of applications and industries is the Dispohomo Reactor suitable for?

A: It is ideal for dispersion, homogenization, and emulsification processes involving liquids, creams, and gels. Typical applications include pharmaceuticals, cosmetics, chemicals, and food processing, providing versatile solutions for manufacturers, fabricators, dealers, and suppliers across various sectors.Q: When should I consider using the jacketed vessel option?

A: The jacketed vessel is advisable when your process requires precise temperature control-either heating or cooling-for sensitive formulations or temperature-dependent reactions. It supports working temperatures from ambient up to 120C, ensuring product stability and consistency during mixing.Q: Where can the Dispohomo Reactor be installed under different production setups?

A: The system is designed for flexible mounting arrangements, including top, side, or bottom entry, and comes as a floor-mounted skid system. This adaptability enables installation in varied production spaces, from compact labs to large-scale industrial plants.Q: What is the CIP (Clean-In-Place) capability and its benefit for operations?

A: CIP design allows the reactor to be cleaned automatically without disassembly. Cleaning solutions are circulated internally to remove residues and contaminants, saving time, reducing manual labor, and minimizing production downtime, particularly important in sanitary and GMP-regulated environments.Q: How does digital process control enhance the use of the Dispohomo Reactor?

A: The digital display and programmable controls enable precise adjustment of speed, temperature, and mixing programs. Optional PLC automation integration facilitates recipe management and process reproducibility, improving efficiency and maintaining consistent product quality.Q: What are the main safety features included in the Dispohomo Reactor?

A: The reactor is equipped with overload protection, an emergency stop function, and interlocking guards to safeguard operators. The mechanical double shaft seal with cooling further enhances operational safety and ensures robust sealing, even at high pressures and viscosities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pharmaceutical Machinery Category

Tablet Coating Pan

Minimum Order Quantity : 01 Piece

Material : Stainless Steel

Control Mode : SemiAutomatic

Computerized : No

Capacity : 30150 kg per batch

Color : Silver

Sigma Mixer With Extruder Screw

Material : Mild Steel / Stainless Steel (contact parts)

Control Mode : Other, SemiAutomatic / Fully Automatic

Computerized : No

Capacity : 50 Liter to 5000 Liter

Color : Industrial Grey / Blue

Homeopathic Liquid Medicine Making Machine

Material : Stainless Steel

Control Mode : Automatic

Computerized : Yes

Capacity : 100200 Liters/hour

Color : Silver

Semi Auto Bottle Filling Machine

Material : Stainless Steel

Control Mode : SemiAutomatic

Computerized : No

Capacity : 5001200 Bottles/Hour

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry