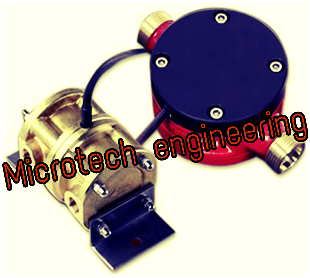

DIFFERENTIAL PRESSURE TRANSMITTER

DIFFERENTIAL PRESSURE TRANSMITTER Specification

- Temperature Range

- -20C to +85C

- Cleaning Method

- Wipe/External cleaning only

- Connecting Type

- 1/4 NPT Female (standard)

- Media Type

- Gas, Liquid, or Steam

- Pressure

- 0 to 16 bar (custom ranges available)

- Efficiency (%)

- 0.1% FS

- Condition

- New

- Material

- Stainless Steel

- Construction

- Weatherproof housing

- Weight

- Approx. 0.6 kg

- Shape

- Rectangular with process connections

- Feature

- High accuracy, Compact design, Easy installation, Stable and reliable output

DIFFERENTIAL PRESSURE TRANSMITTER Trade Information

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Western Union, Paypal, Cheque

- Delivery Time

- 1 MONTH Months

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Central America, Africa, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- AN ISO 9001:2015 CERTIFIED

About DIFFERENTIAL PRESSURE TRANSMITTER

Applications & Usage in Industrial Plants

This differential pressure transmitter is ideally suited for critical plant operations in industries handling gas, liquid, or steam. Its kingly precision ensures process control in filtration, flow measurement, or pump monitoring. Easy installation on a 2-inch pipe or via direct mount makes it flexible for varied setups. Its perfect for measuring differential pressure across filters, heat exchangers, or pipelines, supporting both new and existing plant infrastructures. Simply connect using the 1/4 NPT Female process port for immediate use.

Certification, Market Reach & Logistics

Certified with optional ATEX explosion-proof standards, the transmitter ensures assured safety and performance. The main domestic market covers Indias industrial sector, catering to dealer, distributor, exporter, retailer, and more. Upon arrival at the designated FOB port, the transmitter undergoes secure packing and prompt dispatch. Estimated delivery times fit strict project schedules, ensuring that your plant benefits from outstanding service and minimized downtime from order to installation.

FAQs of DIFFERENTIAL PRESSURE TRANSMITTER:

Q: How is the differential pressure transmitter installed in a plant environment?

A: This transmitter can be easily installed using its 2-inch pipe mount or via direct mount configuration. The standard 1/4 NPT Female process connection allows for secure attachment to piping systems handling gas, liquid, or steam.Q: What are the main benefits of using this differential pressure transmitter?

A: The primary benefits include high accuracy (0.1% FS), robust stainless steel construction, reliable 4-20 mA output, optional HART communication, and resilience against weather and overpressure, making it perfect for demanding industrial applications.Q: When should the explosion-proof (ATEX) model be chosen?

A: The explosion-proof (ATEX certified) version should be selected for installations in hazardous areas where explosive gases may be present, ensuring regulatory compliance and enhanced safety.Q: Where can zero and span adjustments be accessed?

A: Zero and span adjustments are conveniently accessible via external pushbuttons on the housing or remotely via the HART protocol, eliminating the need to open the transmitter or interrupt the installation.Q: What process fluids can be measured with this transmitter?

A: Designed for maximum versatility, the transmitter can measure the differential pressure of gases, liquids, or steam, making it suitable for diverse plant requirements and applications.Q: How does the device maintain its efficiency in harsh environments?

A: With IP65/IP67 protection, weatherproof housing, and stainless steel construction, the transmitter resists dust, moisture, and corrosive conditions, ensuring stable, long-term operation even in challenging industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in flow meters Category

TURBINE FLOW SENSOR

Temperature Range : 20C to +120C

Feature : High Accuracy Measurement, Low Pressure Drop

Weight : Depends on model

Material : Stainless Steel

Construction : Other, Rugged Industrial

Connecting Type : Other, Threaded/Flanged

Thermal Mass Gas Flow Meter

Temperature Range : 20C to +120C (sensor dependent)

Feature : High accuracy, No moving parts, Digital display, Direct mass flow measurement, Low maintenance

Weight : Approx. 25 kg (depends on model)

Material : Stainless Steel

Construction : Other, Integral or remote sensor design

Connecting Type : Other, Flanged/Threaded/Insertion

FUEL CONSUMPTION FLOWMETER

Temperature Range : 10C to +60C

Feature : Fuel Consumption Monitoring

Weight : Approx. 980 g

Material : Stainless Steel

Construction : Other, Robust Industrial Grade

Connecting Type : Threaded

VORTEX FLOW METER

Temperature Range : 40C to +250C (standard), high temperature type up to +350C

Feature : Measures volumetric flow of liquids, gases, and steam using vortex technology

Weight : Varies by model and size (typically 1.5 kg 8 kg)

Material : Stainless Steel

Construction : Other, Robust, compact body with inline and insertion type options

Connecting Type : Other, Flanged, Wafer, or Threaded (depending on model and size)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry